ACCESSORIES FOR PSA ONLINE AND OFFLINE INSTRUMENTS FOR Hg IN NATURAL GAS

P S Analytical have developed a range of accessories for your Online and Offline Instruments. |

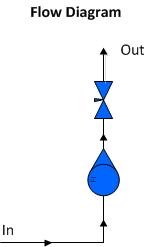

WET GAS FLOW METER |

|

The PSA 10.640 series Primary Pressure Reduction (PPR) Systems are designed to reduce the pressure of sample streams prior to a sampling system. Primary Pressure Reduction systems are typically used to decrease the pressure of hydrocarbon sample streams prior to sample transport to the 10.540 series Online Sampling System or PSA 10.547 Offline Sampling System. Reasons for using Primary Pressure Reduction include:

|

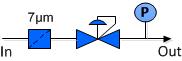

For liquefied sample streams such as LPG or butane, flash vaporisation using a PPR close to the sample point is recommended to avoid the use of liquid bypass configurations. A Primary Pressure Reduction comprises an insulated heated pressure regulator, suitable for use in a zone 1 or 2 hazardous area, (ATEX and IECEx Certification available) a 7 µm pre-filter to prevent particulate from the sample stream entering the regulator, a gauge to view the outlet pressure and associated stainless steel fittings. (Connections are ¼ in. compression fittings.) |

|

The PPR systems have been proven for sampling mercury in hydrocarbon sample streams. Heating the regulator overcomes Joule-Thomson cooling, preventing condensation and losses in the cooled sample stream. The unique spiral machined heater sheath in the heated pressure regulator ensures efficient heat transfer to avoid condensation occurring the in the regulator. For sample streams with very low mercury concentrations and/or highly variable concentrations, SilcoNertTM coated PPR systems are optionally available. |

|

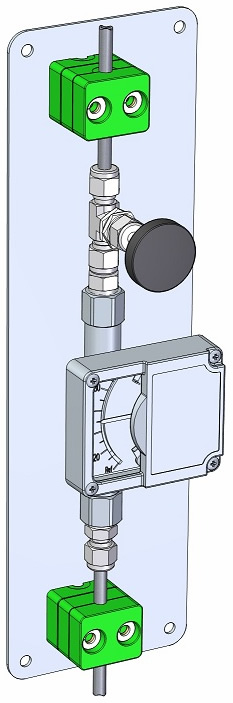

The Primary Bypass Flow Control and Measurement Kit includes an armoured metal tube variable area flowmeter, sized and calibrated for a sample flow rate of 10 L min‑1 (actual) in the sample delivery lines, a needle value for flow control, all mounted on a stainless steel plate to facilitate installation. Connection types: Inlet ¼ in. compression fitting A pressure differential is required between inlet and outlet to ensure adequate flow. |

|

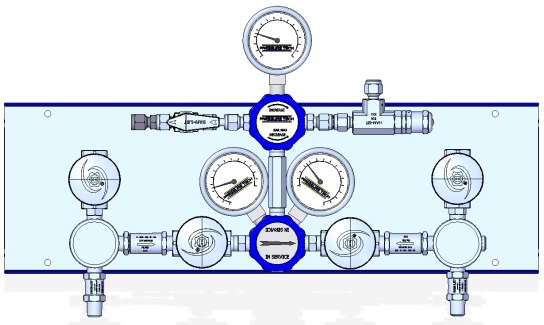

SEMI AUTOMATIC CHANGEOVER PANEL |

|

|

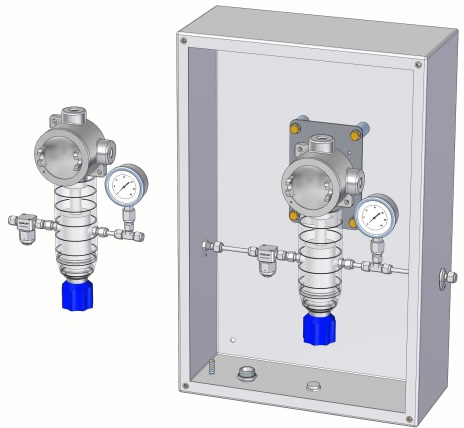

The semi-automatic changeover panel allows the simultaneous connection of two carrier gas cylinders (or cylinder banks) to an online analyser, with automatic changeover from one cylinder to the other as the first cylinder is depleted. It can be used with either argon or nitrogen carrier gas. The panel consists of two single stage pressure regulators built into a single body, which are set to allow a continuous gas supply from two cylinders. The main regulator (left-hand side) is set to a pressure 2 bar higher than the standby regulator (right-hand side). As the pressure from the main cylinder falls, the backup regulator automatically cuts in provide the gas flow. When the handle is turned back to the main regulator, the inlet pressure continues from this side. The cylinder in use is indicated by an arrow on the selection handle. |

An outlet regulator, including a safety pressure relief valve is included at the outlet of the auto-changeover to regulate the gas supply to the required output pressure. The auto-changeover panel incorporates full safety-pattern gauges, indicating each cylinder’s contents and the output pressure; isolation valves for each side and the outlet and high pressure vent valves to facilitate cylinder replacement. Non-return valves, 1 m long high pressure hoses with anti-whip cables and cylinder connectors are also included for each side. |

|

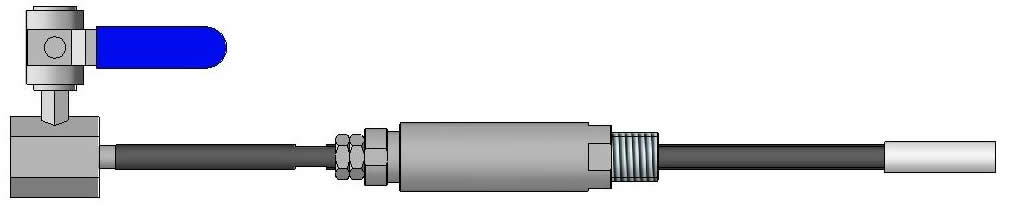

N670P100 SERIES DIRECT DRIVE MEMBRANE PROBE WITH REGULATOR

The N670P100 Series Direct Drive Membrane Probe with Regulator are low dead-volume adjustable length, membrane tipped probes incorporating a pressure regulator for sampling Natural Gas and other Hydrocarbon streams. Product Highlights

|

N670P200 SERIES DIRECT DRIVE MEMBRANE PROBE

The N670P200 Series Direct Drive Membrane Probes are low dead-volume adjustable length, membrane tipped probes for sampling Natural Gas and other Hydrocarbon Gas streams. The N670P200 Series Probe does not include a Pressure Regulator. Product Highlights

|

N670P300 SERIES DIRECT DRIVE PROBE

The N670P300 Series Direct Drive Probes are low dead-volume adjustable length, probes for sampling liquids, Natural Gas and other Hydrocarbon streams. The N670P300 Series Probe does not include a pressure regulator or membrane filter; the sample outlets unfiltered and at process pressure. Product Highlights

|

PSA G525T400 TRAP CLEANERThe PSA G525T400 Trap Cleaner Module is designed to be used as a stand-alone module commenting a Sir Galahad System. |

|

|

Product Highlights:

|

To discuss particular requirements and for more detailed information on the above accessories please complete the Information Request Form.