THE DETERMINATION OF MERCURY AND ARSENIC IN DRILLING MUDS AND FLUIDS

Drilling muds and fluids are used in oil and gas drilling operations to help remove rock cuttings and debris, as well as to cool and lubricate the drilling apparatus. The muds also help to stabilises the borehole and limit water ingress. There are many different types of muds and fluids (water based, oil based, synthetic based) and are used depending on the drilling conditions. Nowadays, all drilling muds are highly regulated in their make-up, and in some cases specific combinations are banned from use because of environmental concerns. Water based muds contain clay (to increase viscosity) and barium sulphate (barite – as a weighting agent) as well as a cocktail of other additives to reduce corrosion, increase alkalinity and help lubricate the drill parts. Barite contains high levels of heavy metals such as mercury, arsenic, selenium, lead, cadmium, zinc, copper, chromium which suggest that barites are not inert but can act as a potentially toxic substance if discharged untreated and unmanaged to the surrounding environment. The drilling muds, fluids and cuttings generate a large volume of waste, and these wastes should be managed responsibly. In many regions of the world, drilling fluids and drill cuttings may be discharged to the sea only if they meet certain environmental requirements. |

|

Millennium Merlin & Millennium Excalibur |

|

P S Analytical offer instrumental solutions for this application that uses the Millennium Excalibur for total Sb determinations. The limits of detection for Sb is 10ng/L providing ample analytical performance.

When the Millennium Excalibur is coupled with PSA’s Modular Interface, speciation studies are possible, providing more information on the different Sb forms present. An example chromatogram is provided below.

|

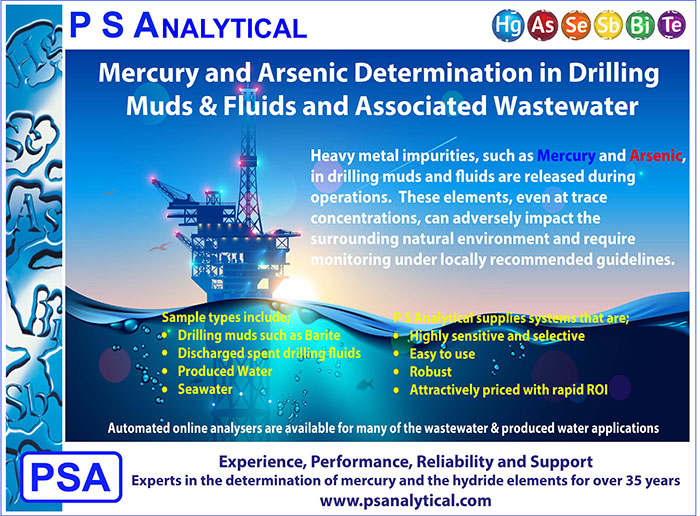

The employment of PS Analytical instruments, the Millennium Merlin (for Hg) and the Millennium Excalibur (for As and the other hydride elements) that employ atomic fluorescence spectrometry, offer an extremely sensitive and accurate determination of Mercury and Arsenic in these challenging matrices. These systems offer the sensitivity and linearity necessary to analyse such samples with the accuracy and precision required. The analysers also allow the determination of these analytes in other environmental matrices; such as seawater, produced water, sediments and sludges. |

The tables below summarise the analyse of several commercial barites for the presence of trace Arsenic and Mercury.

|

|

To discuss particular requirements and for more detailed information on the above products, please complete the Information Request Form.